This was originally sent out as our June 2020 Gas & Oil Industry Newsletter

I. Pipeline Safety Report and Plan

The American petroleum institute (API) recently released its Pipeline Safety Performance Report and Strategic Plan for 2020-2022. The industry continues to make great strides at improving pipeline safety and finding better ways to engage important stakeholders as we move toward the goal of zero damages.

The four main goals in the strategic plan are to promote organizational excellence, improve safety through innovation, increase stakeholder awareness and involvement, and enhance emergency response preparedness. As the industry continues to adopt and implement RP1173 Pipeline safety Management Systems, we do see a very holistic approach to safety, and a change in attitudes, culture, and actions.

II. Tangible Approaches to Improving Pipeline Safety

When identifying ways to improve pipeline safety, we can often look for the low hanging fruit by analyzing identified risks. Outside force damage and excavation damage continue to make up a significant portion of pipeline releases. There are innovations in technologies that warn excavators and potential excavators to the presence of a buried pipelines. While changing the culture of an organization is so very important to improving pipeline safety, it takes time and effort to make any organizational change.

Looking to innovative technologies that provide an unmistakable warning can prevent damages and pipeline releases with almost no investment in time or capital. Communicating with excavators where they are digging is a simple and effective way to prevent 1st, 2nd, or 3rd party excavation damages.

III. Don’t Use Buried Warning Tape; Use Something Better

“It is always cheaper to do things right the first time.” – Phil Crosby

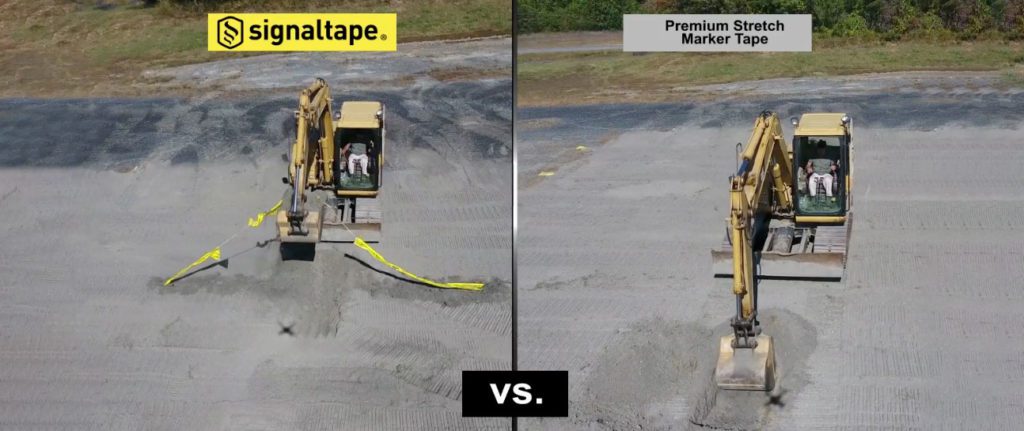

Buried warning tape acts as the last line of defense against excavators digging near your buried facility. The sad reality is that often times, regular warning tape breaks and ends up in the spoils pile before alerting anyone on the job site. Enter Signaltape.

Boasting a 3,000 lb. tensile strength, Signaltape is engineered to be seen.It is a proprietary, low-cost solution developed to prevent excavation damage to buried utilities by providing a visible alert to the presence of a buried utility directly to the equipment operator.

IV. Must Watch

This video is an oldie, but a goodie. Nick Temple’s on-camera debut.

The Inside Scoop: News from the Rhino Office

Overheard: “Quit, try tennis.” – Tom Preston’s hot golf tip.

Free Sign Sample!: Fun Signs for the Office or Home

We’re Turning 30!: 2020 marks 30 years of damage prevention for Rhino Marking and Protection Systems.